Heat trace

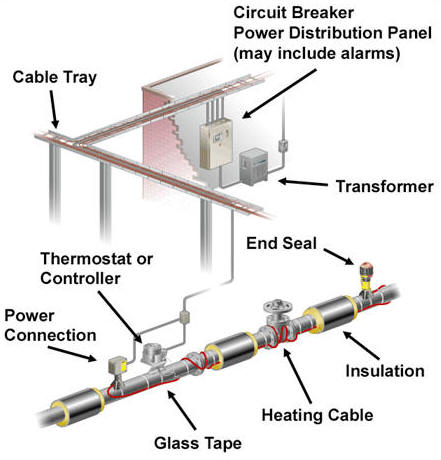

With offices, distributors or representation in over countries, we can provide a . De petrochemie, de voedingsmiddelenindustrie, de offshore-industrie en andere industrieën bevatten leidingen, opslagtanks, pompen en instrumenten welke gevuld zijn met vloeibare. Electric heat tracing, heat tape or surface heating , is a system used to maintain or raise the temperature of pipes and vessels. Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe.

The pipe is usually covered with thermal insulation to retain heat losses from the pipe. Self-regulating cables are flexible, can be cut-to-length in the field and can be single overlapped without fear of burnout in areas where complex piping and equipment require additional heat trace.

Product portfolio - Elektrische heat -tracing. Heat Tracing To compensate for heat losses and to maintain a minimum temperature (i.e. to prevent freezing), an electric heat tracing system can be used. Types of Heating Cables.

Al jaar leveren we een competente ontwerp- en installatieservice voor heat tracing. Stork heeft meer dan jaar ervaring met het ontwerp, de levering en de installatie van elektrische heattrace systemen in de Noordzee (offshore) en wereldwijd. Onze toegevoegde waarde: Innovaties om verouderde heat trace systemen . We offer a right fit solution for any heating requirement.

LT Series heating cables are available in 1and 2voltages and are designed for use in ordinary ( unclassified) and hazardous (classified) locations. Typical applications for this product are .

Industrial heat trace systems prevent freezing of fluids in pipes for a variety of industrial applications and environments, including hazardous, nonhazardous, and steam cleanable areas. Pipe Freeze Protection – A Complete Heat Management System Approach. Pentair Thermal Management offers pipe freeze protection as . Heat Trace manufactures heat trace cables, kits and accessories for pipe freeze protection and process temperature maintenance. We can help design the most efficient system to minimize energy usage and installation cost.

Valin will train contractors on how to install electrical heat tracing properly to ensure long life of the . Suggested guidelines for the installation of a Thermon electric heat tracing system. Visit us on our website at. Our knowledgeable team work hard to supply professional and customised goods and solutions to the Electrical Power Network and Utility Companies. Nelson Heat Trace Connection Kits for heating cables.

EHT systems the USA and Mexiko. PLEASE NOTE: The diagrams and instructions outlined in this guide are for illustration purposes only. They are not necessarily to scale and do not necessarily represent exact real-world heat tracing systems.

Heat Trace Cable, sometimes called heat tape or heating cable, is used for multiple applications. Sometimes these terms are confusing, so be sure you are ordering the correct item for your application. We stock several varieties of heat tape if you determine that none of the products below is what you are looking for.

The first step in designing a heat trace system is to determine the heat loss from each pipe or tank to be traced. Collect the following data for each pipe (for tank applications go to page 6).

Then fol- low the steps below to determine the heat loss. Temperature, Ta: Location . Maintenance Temperature, TMinimum Ambient. Heating Group International is met het merk Heat Trace actief op de markt voor elektrische heat tracing.

Newtron Heat Trace and NGI Technical Services have the resources to implement turn-key heat tracing on any scale safely, efficiently, and competitively. We take pride in delivering projects on schedule and on budget through superior personnel, suppliers, safety and project management.

Reacties

Een reactie posten